Most electric bikes on the market are mainly designed in two motor configurations: Mid-drive motor or Hub motor. In this article, we will talk a bit more about the difference between theses two types of motor.

What are they?

Mid-Drive E-bikes

On a mid-drive e-bike, the electric motor is installed at the five-pass (BB) of the bicycle, which is the stomping center of the whole vehicle. It also needs various sensors (possibly stomping frequency, stomping torque, forward and backward inclination angles or driving speed) to estimate the current movement status of the rider.

Mid-Drive E-bikes

Hub electric motor e-bikes have an electrical motor that is constructed into the hub of the bicycle wheel, located in the center of the wheelset and the Hub motor can be in the front wheel or in the rear wheel.

The hub motor directly powers the wheel it's installed into. To put it simply, it applies torque straight to the wheel. The sensors estimate the rider's motion state. Then the controller calculates how much power to draw from the battery to turn the motor, and then propels the whole vehicle to assist the rider to ride, achieving the goal of saving effort. It operates separately from the bike's drivetrain.

Commonality

In general, these two types of electric bikes share most of the parts that were used on e-bikes. However, some structural components can be vastly different.

Frame

Mid-drive Motor

It needs to be customized based on different styles.

Hub Motor

It can be the same as what bicycles use.

Controller

Mid-drive Motor

It needs to be customized based on different styles.

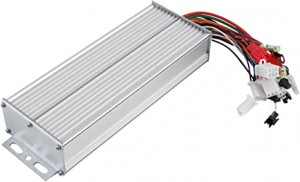

Hub Motor

Most of the controllers you can find on the market are theoretically compatible with hub motors. Consult the manufacturer or dealer about the motor configurations you need to fit with the controller.

Spare Parts

Mid-drive Motor

Need to acquire from manufacturer as they are designed to specifically match the mid-drive motor on specific models or sytles.

Hub Motor

Almost compatible with general bicycle parts on the market.

Note

Mid-drive Motor

Need to acquire from the manufacturer as they are designed to specifically match the mid-drive motor on specific models or styles.

Hub Motor

Almost compatible with general bicycle parts on the market.

Design

Mid-drive Motor

The design of the bottom bracket can be varied greatly.

The crank and cassette are in similar shape.

The wiring for the sensor exposes outside of the frame.

Hub Motor

Similar to most of hub motor e-bikes on the market.

Technology

Mid-drive Motor

Customized parts that fit 350w or lower mid-drive motors are pretty stable on quality.

Hub Motor

Has been deeply developed for mass production and its quality has been tested to be reliable.

Market Proportion

Mid-drive Motor

Accounted for appx 30%-40% in Mountain cycling / daily use sector.

Hub Motor

Accounted for around 50% in all series.

Price

Mid-drive Motor

$300-900

Hub Motor

$200-600

Difference

Hub Motor

Advantages:

Frame and bicycle gm, brushless - brushed motor can be used,

types of motor drive,

different specifications options,

flexible adjustment,

motor power is not limited, (especially in high power advantage significantly), with specifications,

facilitate the vehicle model, configuration design, less restriction, convenient refit stores,

the cycling effect is good, the electronic working system is mature, and price is low

Disadvantages:

the use of the vehicle's center of gravity is higher, no electric cycling resistance is larger

Mid-drive

Advantages:

low center of gravity (mountain cycling has obvious advantages)

no electric cycling is similar to bicycle

Disadvantages:

non-standard BB parts supporting the frame (need to set variable shape, welding and installation accuracy requirements are high)

assembly is tedious and wiring operation is difficult,

the failure rate is high, especially with high power heat dissipation, and volume technical bottleneck is obvious (at present, 1Kw middle motor, large volume, High heat dissipation difficulty, high failure rate, short service life, high cost)

accessories (chain, flywheel, tooth disc technology is not mature, high failure rate, large safety risks)

Post time: Sep-15-2022